What role can 3D scanning play in facilitating the development of drones / UAVs?

Share

What role can 3D scanning play in facilitating the development of drones / UAVs?

3D scanning can significantly assist drone development in several key ways, streamlining the design, testing, and manufacturing processes. Here's how:

-

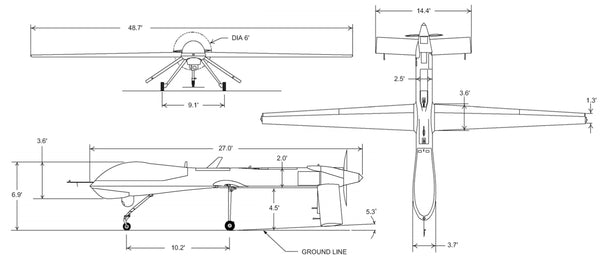

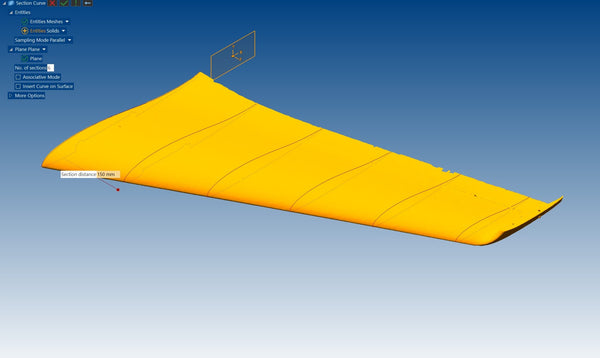

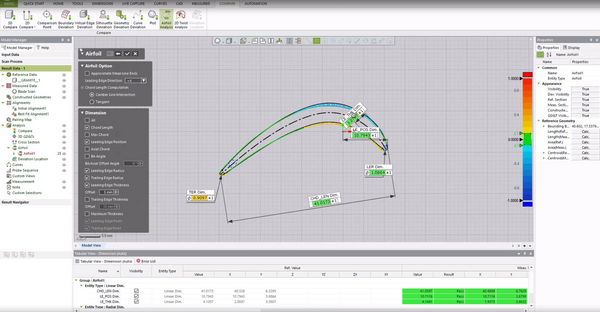

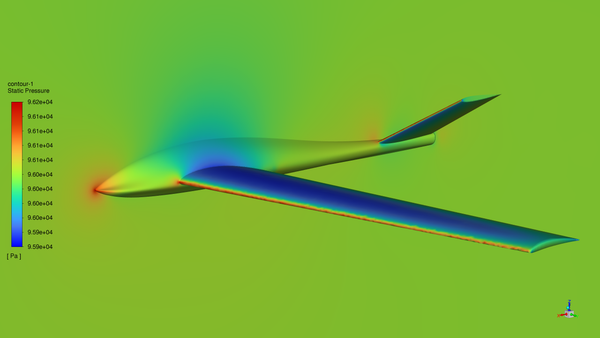

Prototyping and Design Optimization: 3D scanning allows for the rapid prototyping of drone components, enabling developers to quickly iterate on design changes. This process can help in optimizing the aerodynamic properties of drones, reducing weight while maintaining structural integrity, and improving overall performance.

-

Reverse Engineering: Developers can use 3D scanning to reverse engineer existing parts or components, facilitating enhancements or adaptations without the need for original CAD files. This is particularly useful when integrating new technology into existing drone models or when customizing drones for specific applications.

- Quality Control: Throughout the manufacturing process, 3D scanning can be employed for precise quality control, ensuring that each part or assembly meets strict specifications. This can reduce the risk of errors and defects, leading to more reliable and consistent drone performance.

-

Customization for Specific Applications: Drones are used across various sectors, including agriculture, surveying, photography, and surveillance. 3D scanning enables the customization of drones to meet the specific needs of these applications, whether it's altering the drone's shape for better stability and battery efficiency or customizing mounts for cameras and other equipment.

-

Integration of Complex Components: With the advent of advanced electronics and miniaturization of technology, drones are increasingly becoming more complex. 3D scanning helps in the accurate integration of these components by ensuring that the design accommodates all necessary parts precisely, including sensors, cameras, and battery units.

-

Repair and Maintenance: For the maintenance and repair of drones, 3D scanning can provide detailed insights into wear and tear or damage, enabling precise repairs or the replacement of parts. It also allows for the creation of a digital inventory of parts, which can be 3D printed on demand, reducing downtime and maintenance costs.

-

Simulation and Testing: Before physical prototypes are built, 3D models obtained from scans can be used in simulations to predict how drones will perform under various conditions. This can help in identifying potential issues early in the development process, saving time and resources.

By leveraging 3D scanning in these ways, drone developers can enhance the efficiency of their design and manufacturing processes, reduce costs, and accelerate the time to market for new drone technologies. If you’re ready to see how 3D scanners can be used for your project, let 3D Wonders help you open the doorway to a realm of possibilities. Our beginner, professional and metrology 3D scanner bundles come with powerful software that allows you to seamlessly capture any drone design into a polygonal meshes for design, reverse-engineering, or quality control purposes.