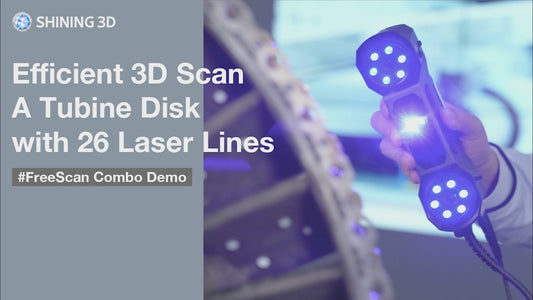

We Help Businesses Improve 3D Design and Inspection Efficiency with Cutting-Edge 3D Scanning Solutions

3D Scanners - Reverse-Engineering - Quality Control - Comprehensive Training

Industry Applications

-

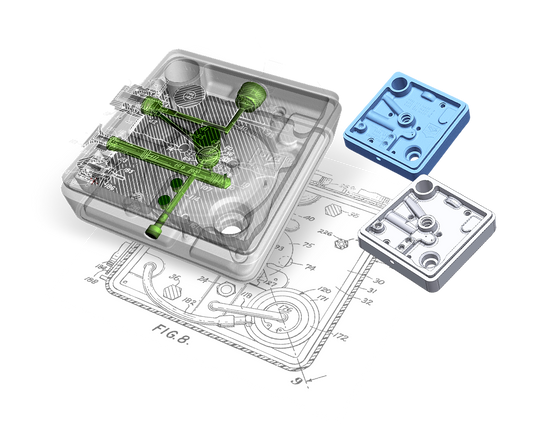

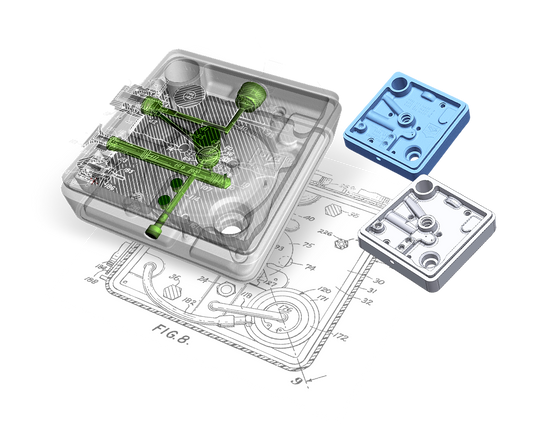

Reverse Engineering

The process of analyzing the construction of a product with the intention of developing a similar or an improved design.

-

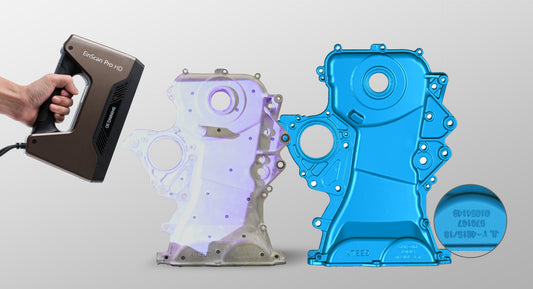

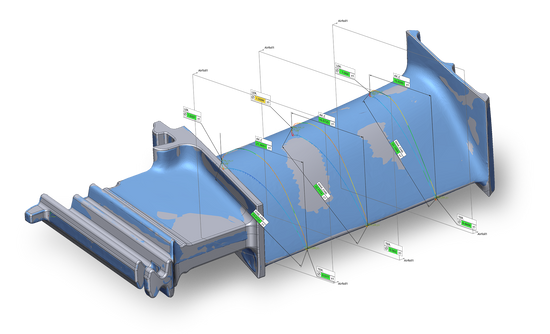

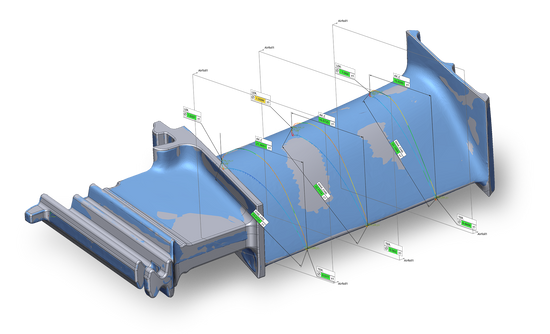

3D Inspection

Quality control against manufacturing defects by comparing 3D scan data from a physical object against a CAD model.

-

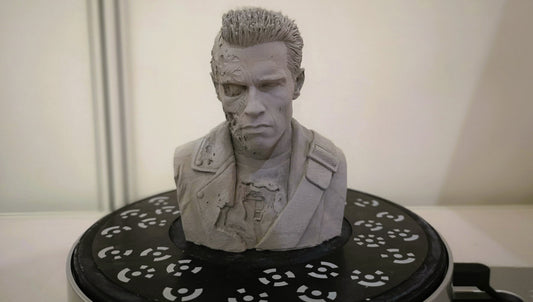

3D Visualization

Modeling an object digitally into 3D form by referencing an existing object rather than creating from scratch.

-

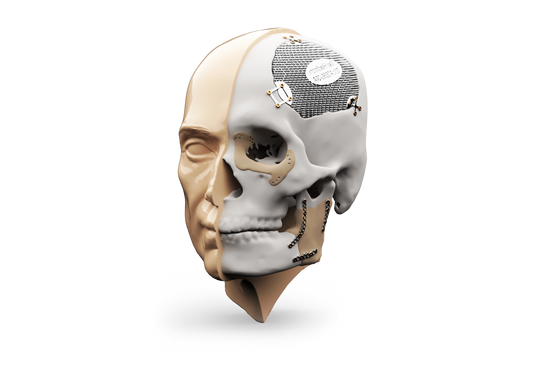

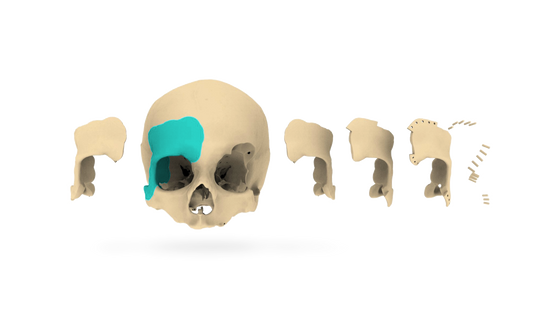

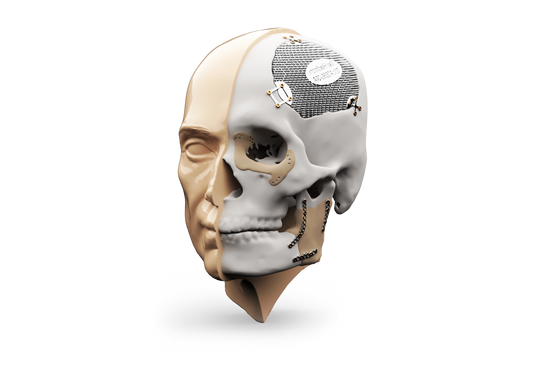

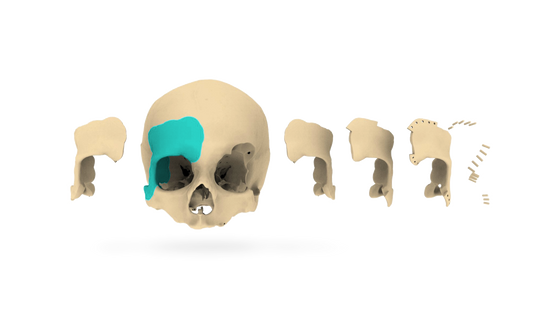

Additive/ Subtractive Manufacturing

3D scanning and manufacturing opens the doors to create customized products in the medical field, automotive and fashion industry, consumer products, and more!

-

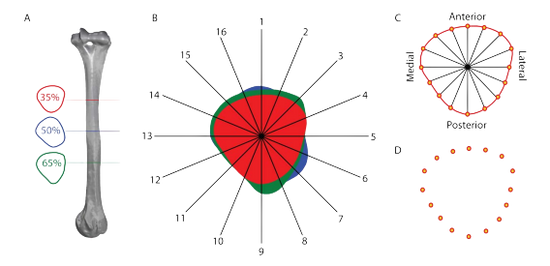

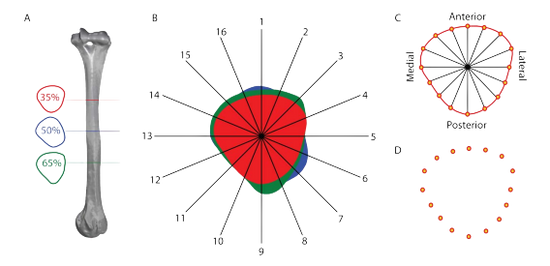

Scientific Measurement

Examine and compare the physical similarities and differences between two or more related objects by collecting measurements for variations and analysis.

-

And Much More!

We are always suprised by the ideas that our customers have! We'd love to partner with you to figure out how 3D scanning technology can assist you.

Our Promises

Why Should You Use 3D Scanners?

SCAN - CREATE - INSPECT

At 3D Wonders, we empower businesses to improve their 3D design and inspection efficiency with cutting-edge 3D scanning solutions. By capturing precise, high-quality digital models of physical objects, 3D scanners streamline workflows, reduce human errors, and minimize the time spent on manual measurements or complex reverse engineering tasks. This improved accuracy leads to faster turnaround time, enabling businesses to accelerate product development cycles and deliver innovations more quickly. Additionally, the ability to inspect and verify designs in real-time ensures better quality control and reduces costly production errors.

If you're ready to try a digital workflow for yourself, shop 3D Wonders' selection of 3D scanners today!