In the realm of 3D reverse engineering, two prominent approaches stand out: parametric modeling and auto surfacing. Both methods serve the same fundamental purpose of reconstructing 3D models from existing objects, but they differ substantially in their methodologies and potential applications.

To help you choose the right 3D modeling technique for your next reverse engineering project, let’s take a closer look at parametric modeling vs. auto surfacing.

What Is Parametric Modeling?

Parametric modeling is a foundational capability in most modern computer-aided design (CAD) software that allows designers and engineers to create models with parameters that can be easily adjusted. The key tools and features that enable parametric modeling in CAD software are:

- Sketch tools: These are used for creating 2D profiles or sketches. They include tools for drawing lines, arcs, circles, rectangles, and more complex shapes. The sketches form the basis of most parametric models.

- Constraints: Constraints control the behavior of sketch entities relative to one another. They include geometric constraints (like parallelism, perpendicularity, and concentricity) and dimensional constraints (which define specific distances, angles, or sizes). Constraints are crucial for maintaining relationships between different parts of the model as parameters change.

- Feature-based modeling tools: These tools allow the creation of 3D features from 2D sketches. Common features include extrudes, revolves, lofts, sweeps, and more. Each feature's dimensions and properties can be driven by parameters.

- Parameters and equations: CAD software allows users to define parameters (like length, width, and diameter) and use equations to establish relationships between these parameters. This enables the creation of scalable and adaptable models where changes in one parameter automatically update others.

- History tree or feature manager: This is a chronological list of all the operations (features) performed on the model. Users can go back and modify any step in the history tree, and the model will update accordingly.

What Is Auto Surfacing and NURBS?

Auto surfacing, often used in the context of computer-aided design (CAD) refers to the automated process of creating complex, smooth, and precise surface models from raw data inputs like point clouds or mesh data. This process is particularly relevant in fields that require high-fidelity surface models, such as automotive, aerospace, and product design. These surfaces are usually created by non-uniform rational B-splines (NURBS), which are a mathematical model commonly used to represent curves and surfaces. They provide great flexibility and precision for handling both analytical shapes (like conical sections) and freeform shapes (like complex organic models). Here's an overview of what NURBS are and how engineers use them:

- Automotive and aerospace industries: Engineers often rely on auto surfacing for designing aerodynamic and aesthetically pleasing surfaces. The method is used to refine the design of vehicle bodies, aircraft fuselages, and other components where surface quality is critical.

- Precision and flexibility: NURBS allow for high precision in modeling, which is essential in engineering applications where accuracy is critical. They also offer flexibility in design modifications.

- Integration with CAD software: Most modern CAD systems support NURBS, making them a fundamental part of the design process. Engineers use CAD software to create, modify, and analyze NURBS-based models.

- Manufacturing and prototyping: Accurate NURBS models are essential for computer-aided manufacturing (CAM) processes like CNC machining and 3D printing. They ensure the manufactured parts match the design specifications precisely.

- Animation and visualization: In engineering, NURBS are also used for creating realistic visualizations and animations of products or components, aiding in design reviews and presentations.

- Finite element analysis (FEA): For structural, thermal, or fluid analysis, NURBS surfaces can be used to create accurate models for finite element analysis, ensuring simulations closely represent real-world scenarios.

- Compatibility and data exchange: NURBS models are widely compatible with various software used in engineering, allowing for seamless data exchange between different systems and disciplines.

Which Should You Use for Your Reverse Engineering Project?

Deciding whether to use parametric modeling in conjunction with auto surfacing (NURBS) for a reverse engineering project depends on several factors related to the nature of the object being reverse-engineered, the intended use of the reverse-engineered model, and the resources available. Here are some considerations to help you make this decision:

Nature of the Object

- Complexity of surfaces: If the object has complex, organic, or freeform surfaces, auto surfacing (NURBS) can be a highly effective method for capturing these shapes accurately from scan data. Parametric modeling can then be used to refine these surfaces or integrate them into a larger design.

- Level of detail required: Parametric modeling offers greater control for highly detailed and precise models. If the reverse-engineered model needs to be modified or optimized, parametric modeling will be beneficial.

Intended Use of the Model

- Manufacturing or prototyping: If the reverse-engineered model will be used for manufacturing or prototyping, parametric modeling can offer more control over the dimensions and tolerances, which are crucial in these processes.

- Modifications and customization: If you plan to modify the design or customize it after reverse engineering, parametric modeling is advantageous. It allows for easy adjustments and design iterations.

- Analysis and simulation: When performing engineering analyses (like stress tests or aerodynamic simulations), a parametric model might be more suitable, as it can be easily adjusted for various scenarios.

Resource and Skill Availability

- Software capabilities: Ensure your CAD software supports both parametric models and NURBS models effectively. Some software may be better suited to one technique over the other.

- Skill level: Parametric modeling requires a higher skill level compared to basic auto surfacing. Ensure your team has the expertise to effectively use parametric modeling tools.

Efficiency and Time Constraints

- Project timeline: Parametric modeling can be more time-consuming than direct modeling techniques, especially for complex objects. Consider your project timeline and deadlines.

- Iterative design needs: If your project involves a lot of iterative design, parametric modeling will be more efficient in the long run, as changes can be made quickly and easily.

Conclusion

- Use auto surfacing / NURBS if the object has complex surfaces, and the primary goal is to create an accurate digital representation of the existing physical form.

- Use parametric modeling if you need high precision, plan to modify the design, or need to perform detailed analyses and simulations.

- Combine both if your project requires the accurate capture of complex surfaces (using auto surfacing), followed by detailed modifications, optimizations, or analyses (using parametric modeling).

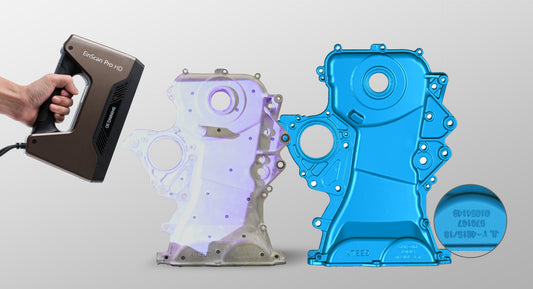

Ultimately, the decision should be based on a balance between the accuracy and detail required, the intended use of the model, and the resources (time, software, skills) available to you. If you’re ready to see where reverse-engineering by parametric modeling or auto surfacing can take your project, let 3D Wonders help you open the doorway to a realm of possibilities. Our reverse engineering 3D scanner bundles come with powerful software that allows you to seamlessly translate polygonal meshes into precise parametric or freeform designs.

1 comment

Very well written article, a rare an pleasant find. Send my regards to the chef please :)