In the contemporary manufacturing landscape, precision and efficiency are paramount. Ensuring that each product meets stringent quality standards is crucial for maintaining brand reputation and customer satisfaction. Traditional inspection methods, while reliable, are often time-consuming and labor-intensive. Enter the trio of metrology 3D scanning, robotic arms, and automated inspection software—technologies that are revolutionizing the inspection process in manufacturing. Together, they enhance both efficiency and effectiveness, transforming how manufacturers approach quality control.

Metrology 3D Scanning: Precision and Detail

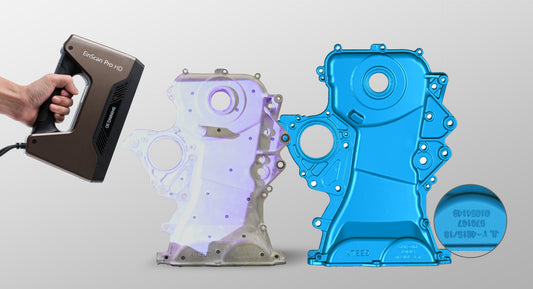

Metrology 3D scanning is a game-changer in the inspection process, offering unparalleled precision and detail with no contact on the physical parts. This technology uses lasers or structured light to capture the exact dimensions and geometry of any object. The resulting digital model can have up to 0.02 mm accuracy to the physical model, and can be compared against the original design specifications or CAD model for GD&T analysis..

Efficiency Gains:

- Speed: 3D scanning significantly reduces the time required to measure complex parts. What once took hours can now be done in minutes.

- Non-Contact Measurement: Since the process is non-contact, it eliminates the risk of damaging delicate parts, making it ideal for inspecting fragile or intricate components.

Effectiveness Improvements:

- High Precision: The level of detail captured by 3D scanners ensures that even minute deviations from design specifications are detected.

- Comprehensive Data: The comprehensive data collected enables thorough analysis, helping to identify systemic issues in the manufacturing process that might otherwise go unnoticed.

Robotic Arms: Automation and Consistency

Robotic arms bring automation to the inspection process, offering unmatched consistency and repeatability. These programmable devices can be equipped with various end effectors, including 3D scanners, to perform inspections with high precision.

Efficiency Gains

- 24/7 Operation: Robotic arms can operate continuously without fatigue, significantly increasing inspection throughput.

- Reduced Human Error: By automating the inspection process, the risk of human error is minimized, ensuring consistent quality checks.

Effectiveness Improvements

- Precision Handling: Robotic arms can handle and inspect parts with precision, maintaining exact positioning and movement throughout the inspection process.

- Versatility: They can be reprogrammed for different tasks, making them highly versatile and adaptable to various inspection needs.

Automated Inspection Software: Data Analysis and Decision Making

Automated inspection software integrates seamlessly with 3D scanning and robotic systems, offering advanced data analysis and decision-making capabilities. This software processes the data collected by 3D scanners, comparing it to the desired specifications and identifying any deviations.

Efficiency Gains

- Real-Time Analysis: Automated inspection software provides real-time feedback, allowing for immediate corrective actions.

- Streamlined Reporting: It generates detailed inspection reports quickly, facilitating faster decision-making and reducing downtime.

Effectiveness Improvements

- Advanced Algorithms: The use of advanced algorithms ensures accurate defect detection and classification, improving the overall quality of inspections.

- Predictive Maintenance: By analyzing trends and patterns in the data, the software can predict potential failures, allowing for proactive maintenance and reducing unplanned downtime.

Synergistic Impact on Manufacturing

The integration of metrology 3D scanning, robotic arms, and automated inspection software creates a synergistic effect that amplifies the benefits of each technology. Together, they streamline the inspection process, enhance accuracy, and ensure consistent quality control.

Efficiency Synergy

- Integrated Systems: The seamless integration of these technologies creates a cohesive inspection system that operates with minimal human intervention.

- Scalability: This integrated approach is highly scalable, making it suitable for both small-scale operations and large manufacturing plants.

Effectiveness Synergy

- Holistic Inspection: Combining these technologies provides a holistic inspection solution that covers every aspect of quality control, from data capture to analysis and reporting.

- Continuous Improvement: The detailed insights gained from this integrated system enable continuous improvement in manufacturing processes, leading to better product quality over time.

In conclusion, the integration of metrology 3D scanning, robotic arms, and automated inspection software represents a significant advancement in the manufacturing inspection process. These technologies collectively enhance efficiency by speeding up inspections, reducing errors, and enabling continuous operation. 3D Wonders is proud to be the distributor of Shining 3D’s metrology grade 3D scanners, Freescan Trio and Freescan Combo, as well as the distributor of 11 Dynamic’s NEXOS Automation Software, we are ready to showcase how they can help you to improve your inspection process. Contact us today and we will show you how you can automate your inspection routines to save time and money.